RESEARCH

OUTFOX WP Descriptions

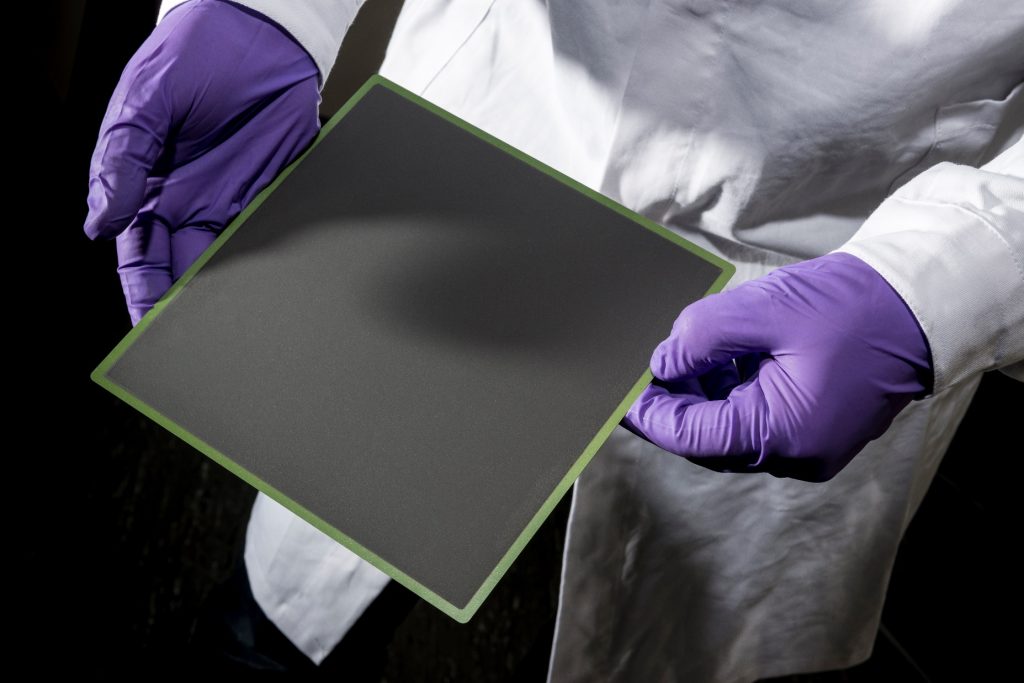

WP1 - Scaled-up solid oxide cell development

The first work package aims to develop scaled-up cells that can operate at current densities of over 0.85 A/cm2 with a degradation rate of less than 1%/1000 hr. To achieve this, the optimal cell size will be analyzed from the cell manufacturing perspective and advanced scaled-up cells will be developed with cell areas up to five times larger than the current state-of-the-art (100-150 cm2). The work will also produce and deliver reference cells and advanced scaled-up cells for testing in WP2 and the 80 kW demonstration in WP5. Four tasks have been defined to accomplish these objectives: producing reference cells for short stack testing and the first 80 kW system testing phase, developing advanced scaled-up solid oxide cells and validating their performance, validating the industrial-scale production of advanced solid oxide cells, and identifying the optimal cell size. The work package will also provide an outlook on the appropriate production method of scaled-up cells and the impact of scale-up on cell production costs, which will serve as inputs for the stack and system cost calculations in WP4.

WP2 – Stack Development and short stack scale testing

WP2 will be dedicated to integrating the upscaled cells developed in WP1 into SOEL stacks. The new cells, featuring larger active areas and reduced thickness, will be the foundation for the development of an optimized stack design. This will involve redefining the SRU and performing modelling activities to ensure the cells’ entire active area is effectively utilized. High current density operation will be evaluated by testing a downscaled version of the optimized cells (developed in WP1) in the current stack platform. This aims at demonstrating low degradation rates (<1%/1000 hr) at short (15 cells) and full scale (119 cells) stacks under system-relevant operating conditions, while achieving more than 2000 hours of operation at this degradation rate.

Such results will verify project targets related to current density, degradation rate, and specific energy consumption. Feedback from the operation of these stacks will be used in the design phase of the system to be developed in WP3. Within this WP, the stacks that will be employed to assemble the 80 kW system will be manufactured.

WP3 – System Development and module scale-up

The main objective of WP3 is to outline a viable pathway to MW-scale SOEL modules for industrial use cases with 100% renewables as a primary energy source, as well as a possibility for integration with industrial processes to provide steam feedstock. The first task of the work package will focus on the conceptual design of a MW-scale SOEL module that incorporates more, and potentially larger, stacks and a higher possible current density. This work aims at establishing an understanding of the value of stack scale-up vs. improvement of multi-stack integration and an optimal module size in terms of CAPEX and capacity utilization, with a particular focus on modularity aspects of the auxiliary systems.

The second part of the work package will involve modifying an existing 250 kWe SOEL system platform developed by the partner Convion for field validation of process and control solutions. This modification aims to improve thermal self-containment and operational flexibility to enable 100% renewables use cases while facilitating increased current density. The designs will be validated in the field at the test site of Shell in WP5 within two 80 kW scale test campaigns.

WP4 – Impact of SOEL scale-up: Techno-economic analysis, Circularity and Roadmap to Pilot(s)

The objective of WP4 is to perform a comprehensive system assessment of the envisioned full-scale SOEL plant via a techno-economic analysis and a medium-term analysis of the environmental aspects with a life-cycle approach related to both manufacturing and operation. The outcomes will inform the definition of a roadmap for the exploitation of SOEL systems up to the multi-MW scale, in line with the project goal of realizing two demo plant projects starting in 2027. The tasks involve the development of a simulation tool for a complete SOEL-based hydrogen production plant, to be used in conducting the techno-economic analysis and evaluate the Levelized Cost of Hydrogen for different use scenarios. A key research element is the analysis of environmental aspects of SOEL deployment at a large scale, which will exploit a life-cycle assessment approach. Finally, the activities will look at the identification of new market segments, studying the market potential and competitiveness of SOEL-based systems through business models, providing insights to create a roadmap for scaling up the systems and evaluating the medium-term impact of advanced SOEL technology.

WP5 – 80 kW Validation

WP5 aims to demonstrate the upscaled SOEL stack and system in an industrially relevant operation scenario, where large-scale deployment of the SOEL technology is attractive. The demonstration and validation of the upscaled SOEL system will be performed at Shell’s Energy Transition Campus in Amsterdam, Netherlands, where the produced hydrogen will be used for a range of applications, including hydrogen refueling stations and Power-to-Liquids processes. This WP will also address safety and operability aspects by performing the HAZOP and acceptance tests of the system, including defining operational protocols based on the results from WP3 and a HAZOP review. The results from the demonstration and validation will be used for further optimization of the SOEL cells, stack, and system design. A feedback loop will be created to ensure that learnings from the system operation in relevant conditions are used to optimize the SOEL technology. The performance of the scaled-up SOEL system design will also be validated to prove the potential to achieve the targets of the Clean Hydrogen JU SRIA.

WP6 – Dissemination, exploitation & outreach

The main goal of the dissemination, exploitation, and outreach activities is to maximize the impact of the project innovations by raising awareness about the potential of SOEL for massive hydrogen production, disseminating non-proprietary results, and working towards realizing two multi-MW demonstrations by 2027. To achieve this aim, the project has specific objectives, such as implementing strategies to protect and commercialize foreground knowledge, developing efficient communication and dissemination strategies, and managing knowledge effectively, including IPR and data management.

The OUTFOX consortium aims to disseminate and exploit the project’s research and outcomes to various audiences, including scientific peers, policymakers, potential business and project partners, and non-scientific consumers. All of the consortium partners will be involved in the activities addressing the communication strategy, dissemination plan, exploitation strategy, and Open Science and Research Management. Regular reviews and updates of the Communication and Dissemination Plan and the Impact and Exploitation Strategy will ensure their effectiveness.

WP7 – Project Coordination

This work package encompasses the essential tasks for ensuring the successful achievement of the project objectives. The consortium will work closely together and exchange knowledge to facilitate fruitful interaction. The project will have a designated interface with the Clean Hydrogen JU to ensure alignment with the JU’s goals and contribute to the program KPIs. Additionally, this work package will handle administration, financial, and legal issues, monitor work progress, and react to risks and challenges in a timely manner. The activities will also address the gender and cultural dimensions of the project to ensure diversity and inclusivity.